Breaking the Bioavailability Barrier: Advanced Strategies to Enhance Drug Solubility and Permeability

This article provides a comprehensive guide for researchers and drug development professionals tackling the pervasive challenge of poor bioavailability.

Breaking the Bioavailability Barrier: Advanced Strategies to Enhance Drug Solubility and Permeability

Abstract

This article provides a comprehensive guide for researchers and drug development professionals tackling the pervasive challenge of poor bioavailability. It explores the foundational science governing the solubility-permeability interplay, details cutting-edge enhancement techniques from cocrystals to lipid-based systems, offers troubleshooting for formulation hurdles, and outlines robust validation methods. By integrating mechanistic insights with practical application and evaluation, this resource aims to equip scientists with the knowledge to strategically optimize compound properties and accelerate the development of effective therapeutics.

The Solubility-Permeability Interplay: Core Principles Governing Oral Drug Absorption

Why Physicochemical Properties are the Foundation of Bioavailability

For researchers and scientists in drug development, the journey of a drug from administration to its site of action is governed by a fundamental principle: its physicochemical properties. These inherent characteristics are the primary determinants of a compound's bioavailability—the fraction of an administered dose that reaches systemic circulation intact [1]. In the context of optimizing compound solubility and permeability, a deep understanding of these properties is not merely beneficial; it is the cornerstone of rational drug design. This guide addresses the specific experimental challenges you face in this critical area, providing targeted troubleshooting and practical protocols to enhance your research outcomes.

FAQs & Troubleshooting Guides

Why is my compound showing poor oral absorption despite high in vitro potency?

This common issue typically arises from a disconnect between a compound's biochemical activity and its biopharmaceutical performance. The most likely culprits are unfavorable physicochemical properties that limit the drug's ability to dissolve and permeate the intestinal membrane.

- Primary Cause: The compound likely falls into Biopharmaceutics Classification System (BCS) Class II or IV, characterized by poor solubility and/or poor permeability [2] [3]. The key parameters to investigate are aqueous solubility, lipophilicity (Log P/Log D), and dissolution rate.

- Troubleshooting Steps:

- Measure Solubility: Determine the equilibrium solubility in biorelevant media (e.g., FaSSIF, FeSSIF) rather than just water. This provides a more physiologically accurate assessment [4].

- Evaluate Permeability: Use in vitro models like PAMPA or Caco-2 monolayers to assess intestinal permeability [2].

- Check the "Rule of 5": Assess molecular weight, Log P, and the number of hydrogen bond donors and acceptors. While not absolute, violations can signal bioavailability problems [4].

You are likely encountering the critical solubility-permeability interplay. When solubility is increased through certain formulation techniques, it can inadvertently reduce the drug's apparent permeability across the intestinal membrane [2] [3].

- Underlying Mechanism: Many solubility-enabling formulations (e.g., those using cyclodextrins or surfactants) work by creating complexes or micelles that encapsulate the drug. This encapsulated drug has a lower free fraction, which is the only form available for passive diffusion across membranes [2] [3].

- Solution: Strive for a balanced optimization. When using solubilizing agents, the goal is to find the concentration that provides an optimal solubility-permeability balance to maximize overall absorption, rather than just maximizing solubility alone [3]. Consider formulation techniques like amorphous solid dispersions that can enhance solubility without significantly compromising permeability [3].

How can I effectively increase the dissolution rate of my poorly soluble drug candidate?

The dissolution rate is directly described by the Noyes-Whitney equation [5]. Your strategy should focus on manipulating the variables in this equation.

Troubleshooting Guide: Target the Noyes-Whitney Parameters

| Target Parameter | Experimental Strategy | Key Considerations & Potential Trade-offs |

|---|---|---|

| Surface Area (A) | Particle size reduction (micronization, nano-milling). | Aggregation Risk: Hydrophobic drugs may aggregate, reducing effective surface area. Use wetting agents or hydrophilic carriers during milling [5]. |

| Solubility (Cs) | - Salt formation (for ionizable compounds).- Amorphous solid dispersions.- Use of cosolvents or complexing agents (e.g., cyclodextrins). | Stability: Amorphous forms are physically unstable and may crystallize. Permeability Trade-off: Complexation can reduce the free fraction of drug, potentially lowering permeability [2] [4] [3]. |

| Diffusion Layer Thickness (h) | Increase agitation in dissolution vessels. | This parameter is largely controlled by physiological conditions in the GI tract (motility), limiting direct experimental control [5]. |

What is the optimal lipophilicity for good oral bioavailability?

Lipophilicity (Log P/Log D) has a non-linear relationship with oral bioavailability. An optimal range exists, balancing membrane permeability with aqueous solubility.

- The Sweet Spot: A Log P between 1 and 3 is generally considered favorable for oral bioavailability [4]. This provides sufficient lipophilicity for membrane permeability while retaining adequate aqueous solubility for dissolution.

- Advanced Metric: Use Ligand-Lipophilicity Efficiency (LLE), which combines potency (IC50) and lipophilicity (Log P), to guide optimization efforts. A higher LLE is generally desirable [4].

- Consider the Target: For CNS drugs, a slightly higher Log P (2-4) may be necessary to cross the blood-brain barrier, but this can further complicate solubility [4].

Experimental Protocols

Protocol 1: Investigating the Solubility-Permeability Interplay

Objective: To systematically evaluate how a solubility-enabling formulation affects the apparent intestinal permeability of a lead compound.

Materials:

- Test Compound: Your poorly soluble drug candidate.

- Solubilizing Agent: e.g., Hydroxypropyl-beta-cyclodextrin (HPβCD) or a surfactant like Polysorbate 80.

- Permeability Model: PAMPA plates or Caco-2 cell monolayers.

- Analytical Instrument: HPLC-MS for quantification.

- Buffer: Biorelevant media (e.g., FaSSIF).

Methodology:

- Solubility Measurement:

- Prepare a series of solutions with increasing concentrations of the solubilizing agent (e.g., 0, 1, 2, 5, 10% w/v HPβCD) in FaSSIF.

- Add an excess of the test compound and agitate for 24-48 hours at 37°C.

- Filter and analyze the supernatant to determine the apparent solubility at each solubilizer concentration.

- Permeability Measurement:

- Using the solutions from Step 1 as donor solutions, perform permeability assays (PAMPA or Caco-2).

- For each solubilizer concentration, measure the apparent permeability coefficient (Papp).

- Ensure sink conditions are maintained if possible.

- Data Analysis:

- Plot the apparent solubility and the Papp against the solubilizer concentration.

- Model the data using a mass transport equation that accounts for the free fraction of the drug, as described in [2]:

P_m = (D_m / h_m) * (C_free / C_total) * K_mwhereP_mis the membrane permeability,C_free / C_totalis the free fraction of the drug, andK_mis the membrane/aqueous partition coefficient.

Protocol 2: Enhancing Solubility via Amorphous Solid Dispersions

Objective: To prepare and characterize an amorphous solid dispersion (ASD) to significantly improve the dissolution rate and apparent solubility of a poorly soluble compound.

Materials:

- Drug Compound

- Polymer Carrier: e.g., PVP K-30, HPMC, or HPC-SSL.

- Solvent: e.g., Methanol, Dichloromethane (or use hot-melt extrusion equipment).

- Instrumentation: Spray dryer or rotary evaporator; Differential Scanning Calorimetry (DSC); X-Ray Powder Diffraction (XRPD).

Methodology:

- Solution Preparation: Dissolve the drug and polymer at a specific ratio (e.g., 1:4 w/w) in a common volatile solvent.

- Drying:

- Spray Drying: Use a spray dryer to rapidly evaporate the solvent, forming solid particles.

- Solvent Evaporation: Use a rotary evaporator to remove the solvent, followed by vacuum drying to remove residual solvent.

- Solid-State Characterization:

- XRPD: Confirm the conversion from crystalline to amorphous state by the disappearance of sharp Bragg peaks and the appearance of a "halo" pattern.

- DSC: Look for the disappearance of the drug's melting endotherm, indicating formation of an amorphous system.

- Dissolution Testing: Perform a dissolution test in 900 mL of FaSSIF at 37°C, comparing the ASD against the pure crystalline drug. The ASD should show a rapid, supersaturated release.

Research Reagent Solutions

Essential materials and their functions for bioavailability-focused experiments.

| Research Reagent | Function & Application |

|---|---|

| Hydroxypropyl-beta-cyclodextrin (HPβCD) | A complexing agent used to enhance apparent solubility via inclusion complex formation. Useful for studying solubility-permeability trade-offs [2]. |

| Fasted-State Simulated Intestinal Fluid (FaSSIF) | Biorelevant dissolution medium that mimics the intestinal environment, providing more predictive solubility and dissolution data than simple buffers [4]. |

| Polyvinylpyrrolidone (PVP) & HPMC | Hydrophilic polymers used in amorphous solid dispersions to inhibit crystallization and stabilize the supersaturated state of a drug, enhancing dissolution [4] [6]. |

| Parallel Artificial Membrane Permeability Assay (PAMPA) | A high-throughput, non-cell-based model for predicting passive transcellular permeability [2]. |

| Caco-2 Cell Line | A human colon adenocarcinoma cell line that, upon differentiation, forms a monolayer with morphology and functional properties similar to small intestinal enterocytes. The gold standard for in vitro permeability assessment [2] [6]. |

Decoding the Biopharmaceutics Classification System (BCS) and its Modern Extensions

BCS Fundamentals & Troubleshooting FAQs

FAQ 1: What is the Biopharmaceutics Classification System (BCS) and why is it critical for oral drug development?

The Biopharmaceutics Classification System (BCS) is a fundamental scientific framework that categorizes drug substances based on their aqueous solubility and intestinal permeability, the two key parameters governing the rate and extent of oral drug absorption [2] [7] [8]. By classifying drugs into one of four classes, the BCS helps researchers identify the rate-limiting step in the absorption process, guiding the strategic development of formulations and, in some cases, waiving costly bioequivalence studies [9] [8].

FAQ 2: My BCS Class II compound shows excellent in vitro solubility but poor in vivo absorption. What could be the issue?

This common problem often points to the solubility-permeability interplay [2] [3]. When you use solubilizing agents like surfactants or cyclodextrins to increase apparent solubility, you may inadvertently decrease the drug's apparent intestinal permeability [2]. The increased solubility often comes from the drug being incorporated into micelles or complexes, which reduces the free fraction of the drug available to permeate the intestinal membrane. Your formulation may be enhancing solubility at the cost of permeability, leading to no net gain in absorption. To troubleshoot, measure the apparent permeability in the presence of your solubilizing formulation, not just in simple buffers [3].

FAQ 3: Are in vitro permeability results from models like Caco-2 reliable for BCS classification?

In vitro models like Caco-2 and PAMPA are widely used and accepted for predicting human intestinal permeability for BCS classification purposes [7] [8]. However, they have limitations. These systems may not fully replicate the human in vivo environment, particularly for drugs that are substrates for intestinal transporters or metabolizing enzymes [10]. For definitive BCS classification, the US Food and Drug Administration (FDA) prefers human pharmacokinetic data, such as the extent of absorption determined by mass balance studies or relative to an intravenous dose [8].

FAQ 4: When is a biowaiver justified for my drug product?

According to regulatory guidelines from the FDA and WHO, biowaivers for in vivo bioequivalence studies are scientifically justified for:

- BCS Class I drugs: High solubility, high permeability, and rapid dissolution [8].

- BCS Class III drugs: High solubility and rapid dissolution, provided the formulation contains no excipients that can significantly affect intestinal permeability or transport [8]. Biowaivers for BCS Class II and IV drugs are generally not recommended due to their solubility-limited absorption [8].

BCS Class Definitions and Characteristics

The BCS categorizes active pharmaceutical ingredients (APIs) into four classes based on solubility and permeability characteristics [7] [8].

Table 1: The Four BCS Classes and Their Characteristics

| BCS Class | Solubility | Permeability | Rate-Limiting Step for Absorption | Examples |

|---|---|---|---|---|

| Class I | High | High | Gastric emptying | Metoprolol, Paracetamol [7] |

| Class II | Low | High | Dissolution | Carbamazepine, Nifedipine [2] [3] |

| Class III | High | Low | Permeability | Cimetidine [7] |

| Class IV | Low | Low | Variable (often poor bioavailability) | Bifonazole, Taxol [7] [8] |

Regulatory Definitions

- High Solubility: The highest dose strength is soluble in 250 mL or less of aqueous media over a pH range of 1.0 to 6.8 at 37°C [8].

- High Permeability: The extent of intestinal absorption in humans is determined to be 90% or higher [8].

- Rapid Dissolution: Not less than 85% of the labeled drug amount dissolves within 30 minutes using standard USP dissolution apparatuses [9].

The Solubility-Permeability Interplay: A Critical Principle

A modern extension of the BCS framework is the recognition of the solubility-permeability interplay. When formulating poorly soluble (BCS Class II) drugs, simply increasing the apparent solubility does not guarantee improved oral absorption, as the formulation may simultaneously reduce the drug's permeability [2] [3].

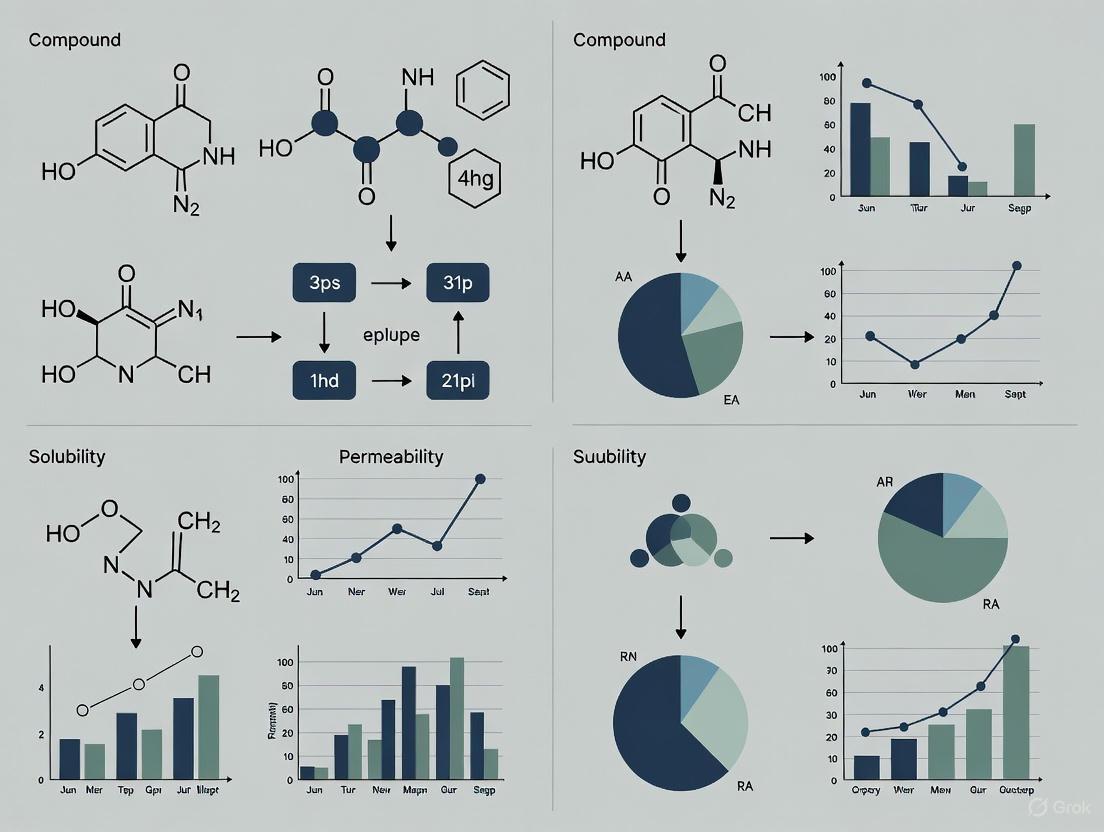

The following diagram illustrates this key relationship and its impact on the overall absorption process.

Experimental Protocol: Assessing the Solubility-Permeability Trade-off

Aim: To evaluate the effect of a solubility-enabling formulation (e.g., cyclodextrin or surfactant) on both the apparent solubility and the apparent permeability of a BCS Class II drug candidate.

Materials:

- Test drug compound

- Solubilizing agent (e.g., HP-β-Cyclodextrin, SLS)

- Permeability model (e.g., PAMPA plates, Caco-2 cell monolayers)

- Dissolution apparatus (USP Apparatus I or II)

- HPLC system with UV detector for quantification

Methodology:

- Solubility Measurement:

- Prepare a series of solutions with increasing concentrations of the solubilizing agent.

- Add an excess of the drug to each solution and agitate in a water bath at 37°C for 24 hours.

- Filter and analyze the supernatant to determine the equilibrium solubility.

- Permeability Measurement (using PAMPA):

- Prepare donor solutions with the drug at a fixed concentration in the presence of the same range of solubilizer concentrations used in the solubility study.

- Use a 2% dioleylphosphatidylcholine in dodecane membrane [2].

- Measure the apparent permeability coefficient (Papp) of the drug at each solubilizer concentration.

- Critical Step: Perform experiments at different stir rates to understand the contribution of the unstirred water layer [2].

Interpretation: Plot both apparent solubility and apparent permeability as a function of solubilizer concentration. The optimal formulation concentration is where the product of solubility and permeability is maximized, not where solubility alone is highest [2] [3].

Advanced Formulation Strategies for BCS Class II Compounds

Table 2: Techniques to Enhance Solubility and Manage Permeability for BCS Class II Drugs

| Technique | Mechanism | Key Consideration for Permeability |

|---|---|---|

| Cyclodextrin Complexation | Formation of water-soluble inclusion complexes [2]. | Reduces free drug concentration, potentially decreasing permeability. The trade-off must be quantified [3]. |

| Lipid-Based/SEDDS | Solubilization and presentation of drug in lipid droplets [9]. | May enhance permeability by facilitating transport via the lymphatic system or through interaction with bile salt micelles. |

| Amorphous Solid Dispersions | Creation of high-energy, non-crystalline solid forms with higher apparent solubility [3]. | Can overcome the trade-off by increasing the free drug concentration in solution without using complexing agents that bind the drug [3]. |

| Particle Size Reduction (Nanoinization) | Increases surface area for dissolution (Noyes-Whitney equation) [9]. | Generally does not negatively impact permeability, as it does not rely on complexation. |

| Surfactant Use | Micellar solubilization above the critical micelle concentration (CMC). | Can decrease apparent permeability by sequestering drug in micelles, reducing free fraction [3]. |

The Scientist's Toolkit: Key Research Reagents and Materials

Table 3: Essential Research Reagents for BCS-Related Studies

| Item | Function in Experiment |

|---|---|

| Hydroxypropyl-β-Cyclodextrin (HP-β-CD) | A commonly used cyclodextrin derivative to form inclusion complexes and enhance drug solubility [2]. |

| Sodium Lauryl Sulfate (SLS) | Anionic surfactant used to simulate the solubilizing effect of bile salts or to enhance dissolution in vitro [11]. |

| Caco-2 Cell Line | Human colon adenocarcinoma cell line that, upon differentiation, forms monolayers with properties similar to small intestinal enterocytes. A gold-standard model for predicting permeability [10] [8]. |

| PAMPA Plate | Parallel Artificial Membrane Permeability Assay plate for high-throughput, non-cell-based assessment of passive transcellular permeability [2] [10]. |

| Simulated Intestinal Fluids (e.g., FaSSIF/FeSSIF) | Biorelevant media containing bile salts and phospholipids that mimic the fasting and fed state composition of human intestinal fluid, providing more predictive dissolution and solubility data [11]. |

Experimental Workflow for BCS Classification

The following diagram outlines a systematic experimental approach for classifying a new chemical entity according to the BCS.

Frequently Asked Questions (FAQs)

Q1: Why is there often a trade-off between enhancing a compound's solubility and maintaining its permeability?

A: This trade-off exists because many solubility-enhancing excipients work by encapsulating or associating with drug molecules, which can reduce the free fraction of the drug available to passively diffuse across cell membranes. Passive diffusion, a key mechanism for permeability, requires the drug to be in its free, unbound form. When a drug is trapped within micelles (e.g., by surfactants like SLS) or encapsulated in cyclodextrin complexes, the large size of the resulting complex or the entrapment of the drug can hinder its ability to cross the lipid bilayer [12] [13]. Essentially, while the total drug concentration in solution (free + bound) increases, the concentration of the permeable, free drug may decrease, creating an inverse relationship between equilibrium solubility and effective permeability [12] [13].

Q2: How does the Biopharmaceutical Classification System (BCS) help in understanding this interplay?

A: The BCS classifies drugs based on their intrinsic solubility and intestinal permeability, providing a framework to anticipate challenges and guide formulation strategies [14] [15]. The system categorizes drugs into four classes, which helps scientists set priorities during development.

Table 1: Biopharmaceutical Classification System (BCS) and Formulation Priorities

| BCS Class | Solubility | Permeability | Key Challenge | Example Drugs |

|---|---|---|---|---|

| Class I | High | High | No major absorption barriers; formulation is often straightforward [15]. | Propranolol, Metoprolol [15] |

| Class II | Low | High | Bioavailability is limited by dissolution rate/solubility. Solubility enhancement is a primary goal [16] [15]. | Carbamazepine, Naproxen [12] [15] |

| Class III | High | Low | Bioavailability is limited by permeability. Enhancing permeability is the key challenge [14] [15]. | Cimetidine, Atenolol [14] [15] |

| Class IV | Low | Low | Significant challenges for both solubility and permeability; often difficult to develop [14] [15]. | Furosemide, Hydrochlorothiazide [14] [15] |

For BCS Class II drugs, the main goal is enhancing solubility without compromising their inherently high permeability [12].

Q3: Are there formulation strategies that can enhance solubility without negatively impacting permeability?

A: Yes, several advanced strategies can simultaneously improve both parameters or mitigate negative effects on permeability:

- Ternary Complexes: Combining a drug with a cyclodextrin (e.g., HP-β-CD) and a third auxiliary substance, such as a natural surfactant like Tea Saponin (TS), can synergistically enhance both solubility and permeability. The surfactant can improve wettability and disrupt membranes slightly, facilitating the transport of the drug-cyclodextrin complex [17].

- Prodrug Approach: Designing an inactive prodrug that has higher solubility and/or lipophilicity than the parent drug can improve both dissolution and membrane permeability. Once absorbed, the prodrug is metabolized to release the active drug in the body [14]. Approximately 13% of FDA-approved drugs between 2012 and 2022 were prodrugs [14].

- Particle Size Reduction to Nano-scale: Creating drug nanoparticles (nanosuspensions) dramatically increases the surface area, which enhances the dissolution rate. The increased dissolution can lead to a higher concentration gradient, a key driving force for passive permeability, thereby improving absorption [15].

- Careful Excipient Selection: The impact of an excipient is highly concentration-dependent. For instance, low concentrations of SLS may reduce permeability by sequestering drug molecules in micelles, while very high concentrations might damage intestinal membranes and artificially increase permeability. Understanding these mechanisms is key to selecting the right excipient at the optimal concentration [12] [13].

Troubleshooting Guides

Problem: Your solubility-enhanced formulation shows excellent in vitro dissolution but poor in vivo bioavailability.

Potential Causes and Solutions:

- Cause 1: Permeability Reduction. The solubility-enhancing excipient (e.g., surfactant, polymer) is reducing the free fraction of the drug available for permeation.

- Solution: Measure the formulation's effective permeability (Peff) using an assay like PAMPA (Parallel Artificial Membrane Permeability Assay). If permeability is low, consider switching to or adding excipients that can act as permeation enhancers (e.g., certain cyclodextrins or bile salts) or reformulating using a prodrug or nanoparticle approach [12] [17] [15].

- Cause 2: Instability in Supersaturated State. Some techniques create a metastable, supersaturated state that rapidly precipitates before absorption can occur.

- Solution: Incorporate precipitation inhibitors (e.g., polymers like HPMC or PVPVA) into the formulation to stabilize the drug in its dissolved state for a longer period, providing a larger window for absorption [13].

Problem: Inconsistent or highly variable permeability results during screening.

Potential Causes and Solutions:

- Cause 1: Variable Experimental Conditions. Factors like pH, temperature, and buffer composition are not tightly controlled.

- Cause 2: Mechanism-Specific Permeability. The compound may enter cells via active transport or endocytosis rather than passive diffusion, which standard artificial membrane assays may not capture.

Experimental Protocols

Protocol 1: High-Throughput Screening of Permeability and Toxicity

This protocol is adapted from a recent high-throughput method for screening cryoprotective agents, demonstrating its utility for rapidly profiling compound properties [18].

1. Principle: The method uses an automated plate reader to track changes in calcein fluorescence from pre-loaded cells. Fluorescence intensity is quenched as cells shrink upon exposure to a hypertonic solution of the test compound. The rate of fluorescence recovery indicates how quickly the compound permeates the cell and drives water back in, allowing for permeability calculation. The same plate is then used for a viability assay.

2. Materials:

- Cells (e.g., Bovine Pulmonary Artery Endothelial Cells) cultured in a 96-well plate.

- Test compounds at desired concentrations.

- Calcein-AM fluorescent dye.

- Automated fluorescent plate reader.

- Isotonic and hypertonic buffer solutions.

3. Procedure:

- Step 1: Load cells with calcein-AM dye according to standard protocols.

- Step 2: Establish a baseline fluorescence reading in an isotonic solution.

- Step 3: Rapidly exchange the solution in each well with a hypertonic solution containing the test compound.

- Step 4: Immediately begin kinetic fluorescence measurements in the plate reader for approximately 15-30 minutes.

- Step 5: Remove the compound solution and replace with an isotonic buffer.

- Step 6: Measure fluorescence again to assess cell viability (healthy cells retain calcein; dead cells release it).

4. Data Analysis:

- Fit the fluorescence recovery data to a mass transport model to determine the solute permeability coefficient (Ps) for each compound [18].

- Calculate cell viability by comparing post-exposure fluorescence to baseline levels.

Diagram 1: High-throughput screening workflow for permeability and toxicity.

Protocol 2: Assessing Solubility-Permeability Interplay Using PAMPA

The Parallel Artificial Membrane Permeability Assay (PAMPA) is a non-cell-based, high-throughput method ideal for early-stage screening of passive permeability [12] [13].

1. Principle: A filter plate constitutes the donor compartment, coated with a lipid-infused artificial membrane. A drug solution in the donor compartment diffuses through the membrane into an acceptor compartment. The apparent permeability (Papp) is calculated by measuring the drug concentration appearing in the acceptor compartment over time.

2. Materials:

- PAMPA plate system (donor and acceptor plates).

- GIT lipid (or other biorelevant lipid mixture).

- Test drug solution with and without solubility-enhancing excipients.

- UV plate reader or LC-MS for quantification.

- Buffer solutions at physiologically relevant pH.

3. Procedure:

- Step 1: Impregnate the filter on the donor plate with the chosen lipid solution.

- Step 2: Add the drug solution (in buffer or buffer with excipient) to the donor wells.

- Step 3: Fill the acceptor plate with a matching buffer (without drug).

- Step 4: Assemble the sandwich (donor plate on top of acceptor plate) and incubate for a set time (e.g., 4-6 hours) at 37°C.

- Step 5: Disassemble the plates and quantify the drug concentration in both donor and acceptor compartments.

4. Data Analysis: Calculate the apparent permeability (Papp) using the formula: Papp = (VA / (Area × Time)) × (CA / CD, initial) Where VA is the acceptor volume, Area is the membrane area, Time is the incubation time, CA is the concentration in the acceptor, and CD, initial is the initial donor concentration.

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for Solubility and Permeability Research

| Category | Item | Function | Key Consideration |

|---|---|---|---|

| Solubility Enhancers | Hydroxypropyl-β-Cyclodextrin (HP-β-CD) | Forms water-soluble inclusion complexes with hydrophobic drugs, enhancing solubility. [17] [12] | Can alter permeability; high doses may cause toxicity. [17] |

| Tea Saponin (TS) | Natural biosurfactant; improves wettability, dissolution, and can act as a permeation enhancer. [17] | Biocompatible and possesses its own pharmacological activities (anti-inflammatory, antibacterial). [17] | |

| Polysorbate 80 (Tween 80) | Surfactant that enhances solubility through micelle formation. [12] [13] | Can reduce permeability by decreasing free drug fraction at low concentrations. [12] | |

| Permeability Assays | PAMPA Kit | High-throughput, non-cell-based method for predicting passive transcellular permeability. [12] [13] | Does not account for active transport or paracellular pathways. |

| NanoClick Assay | Cell-based assay using in-cell Click chemistry and NanoBRET to measure cumulative cytosolic exposure for various uptake mechanisms. [19] | Useful for peptides and molecules that enter via endocytosis or other non-passive mechanisms. [19] | |

| Analytical & Formulation | Polyvinylpyrrolidone (PVP K25) | Polymer used to stabilize amorphous solid dispersions and inhibit precipitation. [12] [13] | Improves dissolution rate and maintains supersaturation. |

| Calcein-AM | Cell-permeant fluorescent dye used in viability and volume-based permeability assays. [18] | Converted to cell-impermeant calcein by intracellular esterases; leakage indicates membrane damage. [18] |

Diagram 2: The interplay between solubility enhancement and permeability outcomes.

Troubleshooting Guides

Guide 1: Inconsistent or Unexpected LogD Values

Problem: Measured LogD values do not align with predicted values or show high variability across experimental replicates.

| Potential Cause | Investigation Steps | Recommended Solution |

|---|---|---|

| Uncontrolled pH [20] | Measure and verify the pH of your aqueous buffer solution. | Use a well-calibrated pH meter and standardize buffers. LogD is pH-dependent; always report the measurement pH. |

| Ionizable Groups [20] [21] | Check your compound's structure for ionizable functional groups (e.g., carboxylic acids, amines). | Account for ionization. Use the relationship: LogD = LogP - log(1 + 10^(pH-pKa)) for monoprotic acids to understand the expected pH profile [20]. |

| Impurities or Degradation | Analyze compound purity (e.g., via HPLC) before and after the experiment. | Use high-purity compounds. Employ fresh solutions and appropriate storage conditions to prevent degradation. |

| Inadequate Phase Separation | Visually inspect the octanol-water mixture for emulsions post-shaking. | Adjust shaking time/force. Allow sufficient time for phase separation. Consider gentle centrifugation to break emulsions. |

Guide 2: Poor Correlation Between Calculated and Experimental LogP

Problem: Software-predicted LogP values significantly differ from experimentally determined ones.

| Potential Cause | Investigation Steps | Recommended Solution |

|---|---|---|

| Algorithm Limitations [22] [23] | Check the "reliability index" or similar confidence metrics provided by the prediction software. | Use a consensus of multiple prediction algorithms (e.g., Classic, GALAS) [22]. Train the model with in-house experimental data for proprietary chemical space [22]. |

| Uncommon Functional Groups | Review the algorithm's training set and documented fragment contributions. | For molecules with unusual structures, rely on experimental determination. Use software that highlights hydrophobic/hydrophilic fragments to spot anomalies [22]. |

| Tautomerism or Conformation | Consider if your compound can exist in multiple stable tautomers or conformations. | Be aware that predictions may be for a single, low-energy state. Experimental conditions may stabilize a different form. |

Guide 3: Challenges in pKa Determination for Low-Solubility Compounds

Problem: Standard potentiometric titration fails due to the compound's poor aqueous solubility [24] [25].

| Potential Cause | Investigation Steps | Recommended Solution |

|---|---|---|

| Low Aqueous Solubility [24] [25] | Observe if the compound precipitates out during the titration. | Switch to an alternative technique like spectrometry or HPLC, which can handle lower concentrations and use co-solvents more effectively [24]. |

| Use of Co-Solvents [25] | If using a water-organic solvent mix, note the type and proportion of the co-solvent. | Extrapolate pKa values from measurements at several co-solvent concentrations. Be aware this can introduce inaccuracies [25]. |

| Overlapping pKa Values | Analyze the titration curve for multiple, close inflection points. | Use techniques like NMR or capillary electrophoresis that can better distinguish between overlapping equilibria [24]. |

Frequently Asked Questions (FAQs)

FAQ 1: What is the fundamental difference between LogP and LogD?

LogP is the partition coefficient of the solely neutral, unionized form of a compound between octanol and water. It is a constant for a given molecule. LogD is the distribution coefficient, which accounts for the partition of all forms of the compound (both ionized and unionized) present at a specific pH [20]. LogD is therefore pH-dependent and provides a more realistic picture of a compound's lipophilicity under physiological conditions.

FAQ 2: Why are LogP and LogD so critical in drug discovery?

Lipophilicity, measured by LogP and LogD, profoundly influences a compound's Absorption, Distribution, Metabolism, Excretion, and Toxicity (ADMET) [20]. A compound must have a balanced lipophilicity to be sufficiently water-soluble for transport in the blood (hydrophilic) yet lipophilic enough to cross lipid cell membranes [20]. Excessively high lipophilicity is often linked to poor solubility, increased metabolic degradation, and toxicity risks [21].

FAQ 3: What are the generally accepted "drug-like" ranges for LogP and LogD?

While optimal ranges can vary by project, common guidelines exist:

- LogP: A value between 2 and 5 is often considered acceptable for good bioavailability [20]. Other analyses suggest a broader qualifying range of -0.4 to 5.6 [21].

- LogD at pH 7.4: An optimum range of 1 to 3 is frequently proposed for good permeability [21]. The Fraction Lipophilicity Index (FLI), a metric combining LogP and LogD, suggests a drug-like range of 0-8 [21].

FAQ 4: My compound has multiple ionizable groups. How do I interpret its LogD profile?

Compounds with multiple ionizable groups will have complex LogD-pH profiles. The LogD will be at a maximum when the pH is such that the molecule is predominantly in its neutral form (closest to its LogP value). As the pH shifts to favor ionization of any single group, the LogD will decrease. The relationship between LogD, LogP, and pKa becomes more complex but follows the same underlying principle of distributing all ionic and neutral species [20].

FAQ 5: What are the key methods for experimental pKa determination and their pros/cons?

The table below summarizes common pKa determination techniques [24] [25]:

| Method | Key Principle | Advantages | Disadvantages |

|---|---|---|---|

| Potentiometric Titration | Measuring pH change upon titrant addition. | Simple, economical, widely used [24]. | Requires aqueous solubility, sensitive to impurities, needs larger sample amounts [24]. |

| Spectrometry (UV-Vis) | Monitoring spectral shifts with pH. | Low sample concentration needed, suitable for insoluble analytes with co-solvents [24]. | Requires a chromophore and a spectral change upon ionization [24]. |

| HPLC | Measuring retention time dependence on pH. | High throughput, impure samples can be used [24]. | Requires method development, indirect measurement [24]. |

| NMR | Tracking chemical shift changes with pH. | Provides structural information, handles multiple/overlapping pKas [24]. | Lower sensitivity, requires more compound, expensive [24]. |

Experimental Protocols

Protocol 1: Shake-Flask Method for Determining LogP/LogD

Principle: This is the classic experimental method for determining partition and distribution coefficients by measuring the concentration of a compound in equilibrated octanol and water phases [20].

Materials:

- n-Octanol (HPLC grade)

- Water or aqueous buffer (e.g., Phosphate Buffered Saline)

- Test compound

- Volumetric flasks or vials with PTFE-lined caps

- Centrifuge

- Analytical instrument for concentration determination (e.g., HPLC-UV, LC-MS)

Procedure:

- Phase Pre-saturation: Pre-saturate water-saturated octanol and octanol-saturated water by mixing the two solvents in a large flask and allowing them to equilibrate overnight with gentle stirring. Separate the phases.

- Sample Preparation: Weigh an appropriate amount of the test compound into a vial. Add a known volume of the aqueous phase (e.g., 5-10 mL) and an equal volume of the octanol phase.

- Equilibration: Seal the vial tightly and shake vigorously on a mechanical shaker for 30-60 minutes at a constant temperature (e.g., 25°C) to reach equilibrium.

- Phase Separation: Allow the vial to stand undisturbed for several hours until the phases separate completely, or use low-speed centrifugation to aid separation.

- Concentration Analysis: Carefully sample from each phase. Dilute samples if necessary and analyze the concentration of the compound in both the octanol and aqueous phases using a calibrated analytical method (e.g., HPLC).

- Calculation:

- For LogD: ( LogD = \log{10}(\frac{[C]{octanol}}{[C]_{aqueous}}) )

- Where ([C]{octanol}) and ([C]{aqueous}) are the concentrations measured in the octanol and aqueous phases, respectively, at a specific pH.

- For LogP: Ensure the pH of the aqueous buffer is chosen such that the compound is >99% in its unionized form (typically pH << pKa for acids, pH >> pKa for bases).

Protocol 2: Potentiometric Titration for pKa Determination

Principle: This method determines pKa by measuring the change in electrical potential (pH) of a solution as an acid or base is added. The pKa is identified as the pH at the half-equivalence point in the titration curve [24] [25].

Materials:

- Automated titrator system with a combined glass pH electrode

- Titrant (e.g., 0.5 M KOH for acids, 0.5 M HCl for bases)

- Ionic strength adjuster (e.g., 0.15 M KCl)

- Purified water (degassed)

- Test compound solution

Procedure:

- System Calibration: Calibrate the pH meter using at least two standard buffers (e.g., pH 4.01, 7.00, 10.01) at the same temperature as the experiment will be conducted.

- Sample Preparation: Dissolve a sufficient amount of the test compound in a known volume of water (or water-co-solvent mixture) containing an inert electrolyte to maintain a constant ionic strength.

- Titration: Place the sample solution under a nitrogen or argon atmosphere to exclude carbon dioxide. Under continuous stirring, add the titrant in small increments. After each addition, allow the potential to stabilize and record the volume of titrant added and the corresponding pH.

- Data Analysis: Plot the recorded pH against the volume of titrant added. The resulting curve will be sigmoidal. The pKa is equal to the pH at the inflection point (half-equivalence point) of the curve. For multi-protic compounds, there will be multiple inflection points.

- Validation: Use a standard compound with a known pKa (e.g., potassium hydrogen phthalate) to validate the experimental setup.

Data Presentation

Optimal Property Ranges for Oral Drugs

The following table consolidates target ranges for key physicochemical properties related to absorption, as discussed in the literature [20] [21].

| Property | Target Range for Good Oral Absorption | Rationale & Context |

|---|---|---|

| LogP | 2 to 5 (or -0.4 to 5.6) [20] [21] | Balances solubility (low LogP) with membrane permeability (high LogP) [20]. |

| LogD at pH 7.4 | 1 to 3 [21] | Reflects optimal apparent lipophilicity for permeability at blood pH. Can be molecular weight dependent [21]. |

| Fraction Lipophilicity Index (FLI) | 0 to 8 [21] | A composite metric combining LogP and LogD. Accommodates >90% of well-absorbed drugs [21]. |

Workflow and Relationship Diagrams

LogP and LogD Relationship

pKa Determination Workflow

The Scientist's Toolkit: Essential Research Reagents & Materials

| Item | Function & Application |

|---|---|

| n-Octanol (HPLC Grade) | The standard non-polar solvent used in shake-flask LogP/LogD determinations for its biomimetic properties [20]. |

| pH Buffers | To control the ionization state of the compound during LogD measurements and pKa titrations. Common buffers include phosphate and citrate [20]. |

| Combined pH Electrode | A critical sensor for potentiometric pKa determination, integrating reference and indicator electrodes [24] [25]. |

| Inert Electrolyte (e.g., KCl) | Used to maintain a constant ionic strength during pKa titrations, which is critical for obtaining accurate results [25]. |

| Standard pKa Buffers | Solutions of known pH (e.g., 4.01, 7.00) for the precise calibration of pH meters before pKa measurements [25]. |

The Role of the Unstirred Water Layer and Membrane Partitioning

Frequently Asked Questions (FAQs)

Q1: What is the Unstirred Water Layer (UWL) and why does it impact my permeability assays? The Unstirred Water Layer (UWL) is a stagnant layer of fluid adjacent to a membrane where solute concentration differs from the well-mixed bulk solution. It creates an additional resistance to mass transfer, causing the measured (effective) membrane permeability to be systematically lower than the true intrinsic membrane permeability. This happens because the permeating solute experiences the concentration gradient across the UWL, not just the membrane itself [26].

Q2: My computational models (e.g., from Molecular Dynamics simulations) predict membrane permeabilities that are 3-4 orders of magnitude higher than my experimental measurements. Could the UWL be the cause? Yes, this is a recognized and potentially dominant source of discrepancy. Many molecular dynamics simulation studies utilize models like the inhomogeneous solubility diffusion (ISD) model but neglect the resistance of the UWL. Incorporating the UWL effect into these models has been shown to yield estimates that agree well with in vivo intestinal permeability data [27].

Q3: Is membrane partitioning the same as nonspecific protein binding? No. While both phenomena decrease the free concentration of a drug, their mechanisms differ. Nonspecific binding to proteins can be erratic, whereas partitioning into membranes is governed by predictable physicochemical interactions like hydrophobicity and charge. For microsomes, evidence suggests that drug sequestration is almost exclusively due to partitioning into phospholipid membranes rather than binding to proteins [28].

Q4: How can I experimentally determine the intrinsic membrane permeability and account for the UWL effect? A method using a rheological droplet interface bilayer (rheo-DIB) device has been developed. This device applies controlled shear stress to the membrane interface via a spinning disk, which reduces the UWL thickness. By analyzing the relationship between the effective permeability and the applied shear stress, both the intrinsic membrane permeability and the UWL thickness can be determined [26].

Troubleshooting Guides

Issue 1: Underpredicted Permeability in Stagnant Assays

- Problem: Measured membrane permeability values are significantly lower than expected or calculated.

- Diagnosis: The UWL effect is pronounced in non-agitated systems (e.g., traditional DIB or PAMPA assays), creating a major resistance to permeation that masks the true membrane permeability [26].

- Solution:

- Introduce Controlled Stirring: Implement a system that can apply defined shear stress to the membrane surface, such as the rheo-DIB chip [26].

- Quantify the Effect: Use the protocol in the table below to measure permeability under varying shear stresses to extrapolate the intrinsic permeability.

Issue 2: Inaccurate Prediction of Membrane Partitioning

- Problem: Models fail to accurately predict the fraction of drug unbound in membrane systems (fum).

- Diagnosis: Reliance on overly simplistic models that do not adequately account for drug charge and orientation.

- Solution:

- Use Charge-Based Models: Employ a descriptor-based model that considers the partitioning of both neutral and ionized species at equilibrium. The partition coefficient (KL) for bases and acids can be predicted using the following relationships [29]:

- For Bases:

Log(L*KL) = Log(K_unionized + K_ionized_base * 10^(pKa-pH)) - Log(1 + 10^(pKa-pH)) - For Acids:

Log(L*KL) = Log(K_unionized + K_ionized_acid * 10^(pH-pKa)) - Log(1 + 10^(pH-pKa))(Where Kunionized, Kionizedacid, and Kionized_base are optimized with physicochemical descriptors like LogP)

- For Bases:

- Consider Membrane Orientation: For more accurate models, an orientation-based approach that selects drug conformations and orientations within the membrane can be used, though this is more computationally intensive [29].

- Use Charge-Based Models: Employ a descriptor-based model that considers the partitioning of both neutral and ionized species at equilibrium. The partition coefficient (KL) for bases and acids can be predicted using the following relationships [29]:

Table 1: Unstirred Water Layer Characteristics and Impact

| Aspect | Quantitative Finding / Value | Experimental Context |

|---|---|---|

| Impact on Permeability | Effective permeability can be ~50% lower than intrinsic permeability [26]. | Resorufin permeating lipid membranes in DIBs. |

| UWL Thickness Range | ~5 µm (water flux across blood cells) to ~100 µm (ions across artificial planar bilayers) [26]. | Various biological and artificial membrane systems. |

| Solute Dependence | UWL thickness depends on the diffusing species. The ratio of UWL thicknesses for two substances equals the third root of the ratio of their diffusion coefficients [30]. | Solute permeation across planar bilayer lipid membranes. |

Table 2: Key Factors Governing Membrane Partitioning

| Factor | Impact on Membrane Partitioning | Key Evidence |

|---|---|---|

| Hydrophobicity (LogP/LogD) | Partitioning increases with increasing LogP/LogD, though the relationship differs for acids, bases, and neutrals [28]. | Linear and quadratic correlations between LogP/D and microsomal partition coefficient (KL). |

| Compound Charge | Hydrophobic amines (bases) partition extensively. Organic anions (acids) have minimal affinity. Neutrals show intermediate behavior [28]. | Different slopes for the LogP vs. KL relationship for each charge class. |

| Phospholipid Composition | Phosphatidylserine membranes have higher affinity for basic compounds due to additional negative charge [28]. | Comparison of partitioning into different membrane types. |

Experimental Protocols

Aim: To measure the intrinsic membrane permeability of a solute by mitigating and quantifying the UWL effect.

Methodology:

- Device Setup: Assemble a rheological droplet interface bilayer (rheo-DIB) chip. The core component is a spinning disk positioned at a defined height (e.g., 1 mm) above a well containing the droplet pairs in an oil phase.

- DIB Formation: Form a planar lipid bilayer between two sub-µL aqueous droplets (e.g., 0.8 µL) immersed in a non-polar phase (e.g., hexadecane) within the chip's well.

- Solute Loading: Load the test solute into one of the droplets (donor) at a known concentration, creating a gradient across the membrane.

- Shear Application: Rotate the disk at controlled angular velocities (e.g., 0 to 200 RPM) to induce laminar flow and shear stress parallel to the membrane, thereby reducing the UWL thickness.

- Concentration Monitoring: Monitor the bulk solute concentrations in the droplets over time (e.g., via fluorescence for a dye like resorufin).

- Data Analysis:

- Calculate the effective permeability (Peff) at each rotation speed.

- Plot Peff against the applied shear stress (or a related hydrodynamic parameter).

- Fit the data to a model that describes the combined resistance of the membrane and the UWL. The plateau or intercept at high shear gives the intrinsic membrane permeability (P_m), while the slope or trend provides an estimate of the UWL thickness.

Aim: To predict the fraction of drug unbound in microsomal incubations using a descriptor-based model.

Methodology:

- Data Collection: Compile experimental fum values for a set of drugs (monoprotic acids, bases, and neutrals) normalized to 1 mg/ml microsomal protein.

- Physicochemical Properties: Obtain the required physicochemical descriptors for each drug: LogP (octanol/water partition coefficient) and pKa.

- Model Application:

- Calculate the lipid binding constant (KL) from the experimental fum:

L * K_L = (1 - fum) / fum, where L is the lipid concentration. - Use the appropriate equation for the compound class (Base or Acid, see Troubleshooting Guide Issue 2) to model Log(L*KL).

- The terms Kunionized, Kionizedacid, and Kionized_base in these equations are themselves functions of LogP and other molecular descriptors, derived from partial least squares (PLS) analysis.

- Calculate the lipid binding constant (KL) from the experimental fum:

- Prediction: For a new drug, use its LogP and pKa to compute K_L and subsequently the predicted fum.

Signaling Pathways and Workflows

Drug Permeation Pathway

Rheo-DIB Experimental Workflow

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for UWL and Membrane Partitioning Studies

| Item | Function / Application |

|---|---|

| Rheo-DIB Chip | A device, typically fabricated from layers of laser-cut PMMA, used to form droplet interface bilayers (DIBs) and apply controlled shear stress via a spinning disk to quantify the UWL effect [26]. |

| Lipids (e.g., Phosphatidylcholine) | Used to form monolayers and the subsequent lipid bilayer in DIB systems. The phospholipid composition (e.g., phosphatidylserine vs. phosphatidylcholine) can affect drug partitioning [26] [28]. |

| Hexadecane (or similar oil) | Acts as the immiscible phase in which the aqueous droplets are suspended to form DIBs [26]. |

| Microsomes | Vesicles derived from the smooth endoplasmic reticulum, used as a source of phospholipid membranes for experimental measurement of membrane partitioning (fum) [29] [28]. |

| Fluorescent Tracer Molecules (e.g., Resorufin) | Small, highly permeable molecules with a strong and linear fluorescent signal used to monitor solute flux in permeability assays [26]. |

| Equilibrium Dialysis Apparatus | Standard equipment for experimentally determining the free fraction of a drug (fum) in microsomal or protein incubations [28]. |

Formulation Arsenal: From Conventional to Next-Generation Enhancement Techniques

Frequently Asked Questions (FAQs)

1. How do physical modifications like nanosizing and amorphization fundamentally improve compound properties?

These techniques primarily enhance the apparent solubility and dissolution rate of poorly water-soluble compounds. Nanosizing increases the total surface area available for dissolution, while converting a crystalline drug to an amorphous form eliminates the high energy of the crystal lattice, reducing the energy barrier for dissolution [31] [32]. This can lead to higher supersaturation levels in the gastrointestinal fluids, which, for permeable compounds, translates to improved absorption and bioavailability [32] [33].

2. Is there a trade-off between increasing solubility and maintaining permeability?

Yes, a solubility-permeability interplay often exists. When using some solubilization techniques, the increase in apparent solubility can sometimes come at the cost of reduced apparent permeability [2]. For instance, if a formulation ingredient (like a cyclodextrin) forms a complex with the drug, the drug's free fraction, which is available for permeation, may decrease. Therefore, the goal of formulation development is to strike an optimal balance between solubility and permeability to maximize the overall oral absorption [2].

3. For which type of compounds is nanosizing most effective for improving absorption?

Nanosizing is particularly effective for highly lipophilic compounds (high Log P). For these compounds, the rate-limiting step for permeation is often diffusion through the unstirred water layer (UWL) [31]. Nanonization can improve permeability by reducing the apparent thickness of the UWL. In contrast, for low lipophilic compounds, where membrane diffusion is the slow step, nanosizing may not improve overall permeability [31].

4. Why are amorphous solid dispersions (ASDs) physically unstable and how is this managed?

The amorphous state is a high-energy state and is thermodynamically unstable, with a natural tendency to recrystallize during storage or dissolution [32] [33]. Stability is managed by:

- Using polymeric carriers (e.g., HPMCAS, PVPVA) that increase the glass transition temperature (Tg) and inhibit molecular mobility [34] [32] [33].

- Formulating co-amorphous systems with low molecular weight co-formers (e.g., amino acids, other drugs) that stabilize the API via strong intermolecular interactions [32].

- Controlling storage conditions (temperature and humidity) to prevent plasticization and recrystallization [33].

5. What are the common signs of recrystallization in an ASD during dissolution testing?

A sharp increase in dissolution concentration followed by a rapid drop is a classic indicator of "spring-and-parachute" behavior, where the amorphous drug dissolves rapidly ("spring") but then recrystallizes in the dissolution medium, leading to a decrease in soluble drug concentration [33]. The solid particles collected during dissolution may also show crystallinity when analyzed by techniques like XRPD [33].

Troubleshooting Guides

Guide 1: Troubleshooting Amorphous Solid Dispersion (ASD) Development

| Problem | Possible Root Cause | Proposed Solution |

|---|---|---|

| Recrystallization during storage | Low Tg of the dispersion; drug loading too high; exposure to moisture (plasticization); weak drug-polymer interactions [32] [33]. | Select a polymer with a higher Tg; reduce the drug loading rate; use airtight packaging with desiccants; explore co-amorphous systems with strong interactors [32] [33]. |

| Rapid recrystallization during dissolution | Inability of the polymer to maintain supersaturation; poor inhibition of surface crystallization [33]. | Change the polymer carrier (e.g., from PVP to HPMCAS which is better at maintaining supersaturation) [33]; add a surfactant to the formulation [34]. |

| Inadequate dissolution improvement | Poor choice of carrier polymer; incomplete amorphization during manufacturing; phase separation [33]. | Re-evaluate polymer selection based on drug-polymer compatibility; optimize manufacturing parameters (e.g., temperature, shear) to ensure complete amorphous conversion [34]. |

| Mottling or color inhomogeneity in final dosage form | Improper mixing of a colored API or dye; migration of dye to the surface during drying [35]. | Change the solvent system or binder; reduce drying temperature; incorporate dry color additives during powder blending and mix thoroughly [35]. |

Guide 2: Troubleshooting Nanosizing and Downstream Processing

| Problem | Possible Root Cause | Proposed Solution |

|---|---|---|

| No permeability improvement despite successful nanosizing | The compound may have low lipophilicity, so membrane diffusion (not UWL) is the rate-limiting step [31]. | Confirm the compound's Log P; for low lipophilicity compounds, consider permeability enhancers instead of, or in combination with, nanosizing. |

| Capping or Lamination of tablets from nanosized powder | Too many fine particles; high compression force; too fast press speed; entrapped air [35]. | Adjust granulate particle size distribution; use pre-compression; reduce press speed; use more efficient binders [35]. |

| Sticking of granulate to punch faces | Granulate not completely dried; lubricant content too low; rough punch surfaces [35]. | Increase drying time; use an efficient lubricant (e.g., magnesium stearate); polish the punch faces [35]. |

| Prolonged dissolution from final tablet | Too much binder used in formulation; no disintegrant; compression force too high [35]. | Use less binder; incorporate a disintegrant or superdisintegrant; decrease compression force [35]. |

Guide 3: Troubleshooting General Manufacturing and Formulation Issues

| Problem | Possible Root Cause | Proposed Solution |

|---|---|---|

| Binding in the die during tableting | Too much moisture in granulate; insufficient lubricant; granulate too hard [35]. | Increase granulate drying time; optimize lubricant type and concentration; improve granulation process to yield softer granules [35]. |

| Weight variation in tablets | Poor flowability of powder/granulate; high variation in particle size or density; press speed too high [35]. | Use glidants or flow enhancers; improve granulation to achieve uniform particle size; reduce press speed to allow for complete die filling [35]. |

| Chemical degradation of API during processing | Exposure to high temperatures or UV light; oxidative degradation [36]. | Optimize processing temperature and time; use amber lighting or cover equipment; purge with inert gas (N2, Argon) [36]. |

| Inconsistent viscosity or phase separation in liquid formulations | Incorrect mixing speed/time; improper heating/cooling rates; wrong order of ingredient addition [36]. | Determine optimal shear and mixing times via DOE; control heating/cooling rates; resequence addition of sensitive ingredients (e.g., add amine post-emulsification) [36]. |

Detailed Experimental Protocols

Protocol 1: Preparation and Evaluation of a Nanosuspension via Wet Milling

Objective: To reduce the particle size of a poorly soluble API to the nanoscale and evaluate its permeability.

Materials:

- API (e.g., Griseofulvin)

- Stabilizers (e.g., PVP K30, AOT, or SLS)

- Milling media (e.g., 0.8 mm Zirconia beads)

- Magnetic stirrer or bead mill

- Dynamic Light Scattering (DLS) instrument

- Pion MicroFlux or similar permeability assay system [31]

Methodology:

- Preparation: Suspend 570 mg of the API in 5.1 mL of a stabilizer solution (e.g., 1.33% PVP K30 / 0.066% AOT) [31].

- Wet Milling: Add the suspension and 24 g of zirconia beads to a milling chamber. Mill using a magnetic stirrer at 700 rpm for 30 minutes. Repeat the milling cycle 4 times with 15-minute intervals to prevent overheating [31].

- Separation: Separate the nanosuspension from the beads by filtration using a syringe with a pore size smaller than the beads [31].

- Characterization:

- Permeability Assessment:

- Use an in vitro tool like the Pion MicroFlux that can measure permeability under non-sink conditions (where the drug is not fully dissolved) to better simulate in vivo behavior [31].

- Compare the permeability of the nanosuspension against a coarse microsuspension of the same API.

Protocol 2: Fabrication of an Amorphous Solid Dispersion (ASD) via Spray Drying

Objective: To create a stable ASD to enhance the dissolution rate and maintain supersaturation of a poorly soluble drug.

Materials:

- API (e.g., Felodipine)

- Polymer carrier (e.g., HPMCAS, PVP K30)

- Organic solvent (e.g., Methanol, Acetone)

- Spray dryer

- Dissolution apparatus

- XRPD, DSC [33]

Methodology:

- Solution Preparation: Dissolve the API and polymer at a specific ratio (e.g., 20:80 w/w) in a suitable organic solvent to create a clear solution [33].

- Spray Drying: Process the solution through a spray dryer, optimizing parameters like inlet temperature, feed rate, and atomization pressure to produce a dry, free-flowing powder [34].

- Characterization:

- Solid State: Use XRPD to confirm the absence of crystalline peaks, indicating successful amorphization. Use DSC to determine the single, elevated Tg of the ASD [33].

- Dissolution Testing:

- Perform dissolution testing (e.g., in pH 6.8 buffer) and compare the profile of the ASD against the pure crystalline API [33].

- Monitor the concentration over time (e.g., 60-120 minutes) to assess the extent and duration of supersaturation. Analyze solids at the end of the test by XRPD to check for recrystallization [33].

- Stability Study: Package the ASD and store it under accelerated conditions (e.g., 40°C/75% RH) for 1-3 months. Periodically sample and analyze by XRPD and dissolution to assess physical stability [33].

Workflow and Relationship Visualizations

ASD Development and Stability Workflow

Drug Permeation and Nanosizing Effect

The Scientist's Toolkit: Key Research Reagents and Materials

| Item Category | Specific Examples | Function & Rationale |

|---|---|---|

| ASD Polymer Carriers | HPMCAS, HPMC, PVP, PVPVA, Soluplus | Stabilize the amorphous drug, inhibit recrystallization, increase Tg, and maintain supersaturation during dissolution [34] [33]. |

| Co-amorphous Co-formers | Amino Acids (e.g., Arginine), Carboxylic Acids (e.g., Citric acid), other APIs | Form molecular-level interactions with the drug to stabilize the amorphous form, often allowing for lower excipient load compared to polymers [32]. |

| Nanosizing Stabilizers | PVP K30, AOT, SLS, Poloxamers | Prevent aggregation of nanoparticles during and after milling by providing steric or ionic stabilization [31]. |

| Tableting Excipients | Magnesium Stearate (lubricant), Microcrystalline Cellulose (binder/bulker), Croscarmellose Sodium (disintegrant) | Enable successful compression of powders into tablets, ensure uniform weight, facilitate disintegration, and prevent sticking and capping [35]. |

| Permeability Assay Tools | Pion MicroFlux, PAMPA plates, Caco-2 cell lines | Provide in vitro models to measure a compound's ability to cross membranes, with some systems capable of testing under non-sink conditions critical for nano-formulations [31] [2]. |

Troubleshooting Guide: Navigating Solubility and Permeability Challenges

This guide addresses common challenges in optimizing drug solubility and permeability through salt formation, cocrystals, and prodrugs.

Frequently Asked Questions

1. Why did my cocrystal formulation fail to improve oral absorption despite significantly higher solubility in vitro?

This common issue often stems from the solubility-permeability interplay. When you increase a drug's apparent solubility through formulations, you may inadvertently decrease its apparent permeability across intestinal membranes [2].

- Root Cause: Permeability is governed by the drug's ability to partition from the aqueous intestinal milieu into the lipophilic membrane. Solubilization techniques often reduce the drug's free fraction available for absorption. For instance, when a drug is entrapped within a cyclodextrin complex or surfactant micelles, the bound drug cannot passively diffuse through the membrane [2] [37].

- Solution:

- Strike a Balance: Aim for an optimal solubility-permeability balance rather than maximum solubility. A moderate solubility increase with maintained permeability can yield better absorption than a large solubility increase with severely compromised permeability [2].

- Use Competitive Agents: In cyclodextrin-based systems, consider adding a competitive agent that can displace the drug from the complex near the absorption membrane, freeing the drug for permeation [37].

- Validate with Biorelevant Media: Conduct permeability studies (e.g., using PAMPA or Caco-2 models) in tandem with solubility studies to assess the net effect on absorption potential [2] [37].

2. How can I predict the stability and supersaturation potential of my pharmaceutical cocrystal?

The cocrystal eutectic constant is a key quantitative property you can measure to predict this behavior [38].

- Root Cause: The performance of a cocrystal is determined not just by its intrinsic solubility, but by its solution phase behavior in relation to the parent drug. Without knowing the eutectic constant, it's difficult to predict regions of thermodynamic stability and the potential for conversion to a less soluble solid form [38].

- Solution:

- Measure the Eutectic Constant (K~eu~): This constant reflects the cocrystal's stability or supersaturation index. It indicates how close the system is to equilibrium and establishes transition points [38].

- Apply Simple Relationships: Use the K~eu~ to predict cocrystal behavior as a function of pH and the presence of drug-solubilizing agents. This allows for the rational selection of formulation conditions to dial in the desired supersaturation index and bioavailability [38].

3. My dipeptide prodrug shows excellent solubility but poor in vivo efficacy. What could be wrong?

The issue likely lies in the design of the promo iety or its metabolic stability [39].

- Root Cause: Dipeptide prodrugs are often designed to be substrates for specific transporters like hPEPT1. However, the choice of amino acids in the dipeptide carrier can drastically influence the prodrug's chemical stability in the gastrointestinal (GI) lumen and its enzymatic susceptibility for activation inside the target cell [39].

- Solution:

- Modify the Promo iety: Structure-activity relationship studies indicate that you can modulate lipophilicity, stability, and activity by varying the dipeptide carrier. For example, a valine (Val) residue directly linked to the drug can improve chemical stability [39].

- Conduct Comprehensive Stability Studies: Evaluate the prodrug's stability in simulated GI fluids and its enzymatic conversion in plasma and target cell homogenates to ensure it reaches its site of action and releases the active parent drug effectively [39] [40].

Experimental Protocols & Data

Protocol 1: Evaluating the Cocrystal Eutectic Constant

Objective: To determine the eutectic constant (K~eu~), a key parameter for predicting cocrystal solubility and stability [38].

Materials:

- Cocrystal and pure API (Active Pharmaceutical Ingredient)

- Relevant buffer or biorelevant medium

- Shaking water bath or incubator

- HPLC or UV-Vis spectrometer for quantification

Methodology:

- Prepare suspensions of the cocrystal and the pure API separately in the same medium.

- Place the suspensions in a constant-temperature environment (e.g., 37°C) with agitation for a sufficient time to reach equilibrium (e.g., 24-48 hours).

- Filter the suspensions and analyze the concentration of both the drug and the coformer in the solution phase.

- Calculation: The eutectic constant (K~eu~) is the ratio of the product of the component concentrations at the eutectic point. For a 1:1 cocrystal (API:Coformer), it is given by [API]~eu~[Coformer]~eu~. The concentrations measured from the cocrystal suspension at equilibrium are used for this calculation [38].

Protocol 2: Assessing the Solubility-Permeability Interplay

Objective: To systematically investigate the trade-off between solubility enhancement and permeability reduction using a parallel artificial membrane permeability assay (PAMPA) [2] [37].

Materials:

- Model drug (e.g., Dexamethasone)

- Solubilizing agent (e.g., β-cyclodextrin, surfactants)

- PAMPA plate system (including lipid membrane)

- Donor and acceptor plates

- UV plate reader or HPLC

Methodology:

- Prepare donor solutions of the drug in buffers containing increasing concentrations of the solubilizing agent (e.g., 0, 2, 5, 10 mM cyclodextrin).

- Add the acceptor solution to the acceptor plate.

- Carefully place the donor plate on top of the acceptor plate and incubate for a predetermined time (e.g., 4-6 hours) at 37°C.

- Analyze the drug concentration in both the donor and acceptor compartments after the incubation period.

- Calculate the Apparent Permeability (P~app~): P~app~ = (V~D~ / (Area × Time)) × (C~A~ / C~D,initial~), where V~D~ is the donor volume, Area is the membrane area, and C~A~ is the concentration in the acceptor compartment.

- Plot P~app~ against the concentration of the solubilizing agent. A decrease in P~app~ with increasing solubilizer concentration confirms the solubility-permeability interplay [2] [37].

Table 1: Performance Comparison of Solubilization Strategies

| Strategy | Example System | Solubility Increase | Permeability / Absorption Note | Key Consideration |

|---|---|---|---|---|

| Cocrystals | Carbamazepine-Saccharin [38] | Orders of magnitude possible | Must be tuned via K~eu~ to manage stability & supersaturation [38] | Solubility advantage is pH- and excipient-dependent [38] |

| Cyclodextrins | Dexamethasone / β-cyclodextrin [37] | Linear increase with CD concentration | Decrease in P~app~ observed in vitro; effect may be less pronounced in vivo [37] | Free drug concentration dictates permeability [2] |

| Ternary Complexes | Decoquinate / HP-β-CD / Tea Saponin [17] | From 0.029 μg/mL to 722 μg/mL | Increase in membrane permeability reported [17] | Auxiliary agent (TS) can enhance both solubility and permeability [17] |

| Dipeptide Prodrugs | Val-Val-ACV; Phe-Gly-ACV [39] | Increased solubility at physiological pH [39] | Improved permeability via hPEPT1 transporter [39] | Stability in GI fluid and efficient enzymatic cleavage are critical [39] |

Table 2: Essential Research Reagent Solutions

| Reagent / Material | Function in Experiment | Key Application Note |

|---|---|---|

| Hydroxypropyl-β-Cyclodextrin (HP-β-CD) | Solubilizing agent that forms inclusion complexes with lipophilic drugs [17] [2]. | High doses may cause toxicity; balance between solubility enhancement and permeability reduction is crucial [17] [2]. |

| Generally Regarded As Safe (GRAS) Coformers | Molecules used to form pharmaceutical cocrystals with an API [38]. | Selection is often based on supramolecular synthons and hydrogen-bonding potential with the API [38]. |

| Tea Saponin (TS) | Natural, amphipathic biosurfactant used as a third auxiliary substance [17]. | Can act as a stabilizer for nanosuspensions and may possess intrinsic pharmacological activity (e.g., anti-inflammatory) [17]. |

| PAMPA Assay Kit | Non-cell-based model for high-throughput assessment of passive transmembrane permeability [2] [37]. | Useful for initial screening of the solubility-permeability interplay; results may require validation with more complex models [37]. |

Strategic Pathways and Workflows

Cocrystal Development Workflow

Solubility-Permeability Interplay

Frequently Asked Questions (FAQs) on LBDDS Fundamentals

Q1: What are Lipid-Based Drug Delivery Systems (LBDDS) and how do they improve the solubility of poorly water-soluble drugs?

LBDDS are advanced pharmaceutical formulations that use lipids (oils, surfactants, etc.) as carriers to enhance the delivery of drugs. They are particularly effective for poorly water-soluble drugs, a significant challenge in drug development as about 90% of new chemical entities and 40% of marketed drugs face bioavailability issues due to poor solubility [41] [42]. They improve solubility and bioavailability through several key mechanisms:

- Maintenance of Drug in Solubilized State: The formulation keeps the drug dissolved within the gastrointestinal (GI) tract, bypassing the slow and often rate-limiting dissolution step [43] [44].

- Stimulation of Intestinal Secretions: Lipid components, especially in self-emulsifying systems, can promote the secretion of bile and pancreatic juices. These endogenous fluids combine with the formulation to form mixed micelles, which further enhance the solubilization capacity for the drug [45] [43].

- Facilitation of Lymphatic Transport: Some lipid-based formulations can promote the absorption of drugs via the intestinal lymphatic system, which partially avoids first-pass metabolism and can increase systemic availability [46].

Q2: When should a formulator choose a softgel capsule over a Self-Emulsifying Drug Delivery System (SEDDS)?

The choice depends on the drug's properties and the target product profile. The following table summarizes the key considerations:

| Formulation Type | Best For | Key Advantages | Common Challenges |

|---|---|---|---|

| Softgel Capsules [44] | • DCS Class IIb drugs (solubility-limited absorption)• High-dose drugs• APIs requiring protection from oxidation | • Proven, commercially scalable technology• Hermetic seal protects fill from oxygen• Rapid shell rupture and content release | • Limited to liquids or low-melting semi-solids• Potential for interaction between shell and fill |

| SEDDS (Liquid) [43] | • BCS Class II & IV drugs• Rapid absorption profiles• Formulations requiring spontaneous emulsification | • Forms fine emulsion in vivo without energy input• Well-known for enhancing bioavailability | • Stability and potential leakage from capsules• Challenges in handling liquid dosage forms |

| S-SEDDS (Solid) [43] | • Combining bioavailability benefits with solid dosage form advantages• Improved stability and patient compliance | • Enhanced physical/chemical stability• Compatibility with tableting and other solid-dose processes | • Complex manufacturing (spray drying, adsorption, etc.)• Risk of damaging the self-emulsifying ability during solidification |

Q3: What is the Lipid Formulation Classification System (LFCS) and how is it used?

The LFCS is a framework introduced by Pouton to categorize LBDDS based on their composition and predicted behavior in the GI tract [46] [47]. It guides formulators in selecting the right excipient mix.

- Type I: Pure oils (triglycerides) that require digestion.

- Type II: Oils blended with water-insoluble surfactants (HLB < 12); form coarse emulsions.

- Type III: Oils, water-soluble surfactants (HLB > 11), and co-solvents; form fine emulsions or microemulsions (further divided into IIIA and IIIB).

- Type IV: Systems containing only water-soluble surfactants and co-solvents (no oils); form micellar solutions [46] [43] [44]. Recent research has explored novel, simplified systems like Binary Lipid Systems (BLS), which consist of only one lipid and one water-soluble surfactant, capable of forming stable self-emulsifying microemulsions and achieving high drug loading in solid dosage forms [47].

Troubleshooting Common Experimental Issues

Q4: Our LBDDS shows promising in vitro solubility but fails to correlate with in vivo bioavailability. What could be the reason?

This is a common challenge in LBDDS development. The discrepancy often arises because traditional in vitro dissolution tests do not fully capture the complex dynamic processes in the GI tract.

- Problem: Standard dissolution methods fail to account for lipid digestion, micelle formation, and drug precipitation upon dispersion [46].

- Solution: Implement more biorelevant in vitro models.

- Protocol: pH-Stat Lipolysis Assay: This model simulates the enzymatic digestion of lipids in the small intestine.

- Setup: Place the LBDDS in a digestion vessel containing a biorelevant medium (e.g., FaSSIF/FeSSIF) at 37°C.

- Digestion: Add pancreatic lipase and co-lipase to initiate lipid digestion.

- pH Control: Use a pH-stat titrator to automatically add sodium hydroxide (NaOH), which neutralizes the free fatty acids released during digestion. The volume of NaOH consumed is proportional to the extent of digestion.

- Sampling: At set time points, sample the vessel. Immediately add a lipase inhibitor to stop the reaction in the sample. Centrifuge or ultrafilter the sample to separate the aqueous phase containing solubilized drug (in micelles) from any precipitated drug.

- Analysis: Quantify the drug in the aqueous phase (representing bioaccessible drug) and the pellet (precipitated drug) using HPLC [46].

- Interpretation: A formulation that maintains a high percentage of drug in the aqueous phase throughout the lipolysis experiment is less likely to precipitate in vivo and has a higher chance of good bioavailability [46].

- Protocol: pH-Stat Lipolysis Assay: This model simulates the enzymatic digestion of lipids in the small intestine.

Q5: Our drug precipitates out of solution after dispersion of the SEDDS in aqueous media. How can this be prevented?

Drug precipitation upon dilution is a major failure mode for SEDDS.

- Problem: The formulation loses its solubilization capacity when it encounters the large volume of GI fluids.

- Solution:

- Reformulate with Long-Chain Lipids: Studies have established that long-chain lipids resist drug precipitation better than medium-chain lipids because their digestion products (long-chain fatty acids) form more robust mixed micelles with bile salts [43].